Roman Engineering: The Backbone of an Empire

Roman engineering combined practicality with innovation, utilizing materials like concrete and brick to construct vast, enduring structures. The adaptability of their methods allowed for architectural achievements that shaped both their empire and future civilizations.

From towering aqueducts that stretched across landscapes to roads that connected an empire, Roman engineering was more than just a technical achievement—it was the foundation of Rome’s enduring dominance. The Romans were not merely builders; they were innovators, problem-solvers, and visionaries who transformed the natural world to suit their needs.

By mastering concrete, perfecting road construction, and designing architectural wonders, they left behind a legacy that still shapes modern engineering. Their creations, many of which have withstood the test of time, speak to their exceptional inventiveness and the strategic brilliance behind their infrastructure.

Innovation and Influence

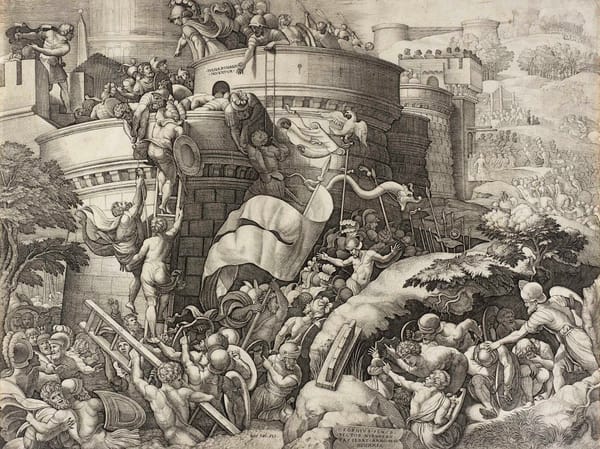

Empires have been defined in multiple ways—by their territorial expanse, longevity, economic power, or military dominance. While the Roman Empire was not the largest in land area or the longest-lasting, its true legacy lies in its engineering and architectural achievements.

Military strength enabled Rome to expand its borders, but it was the Romans' unique ability to build that both symbolized the Empire in its prime and continues to define it today. The materials they used, the construction techniques they perfected, and the architectural styles they pioneered in government buildings, entertainment venues, residential structures, bridges, and aqueducts remain lasting proof to their ingenuity.

The vast scale of Roman construction, its spread across the Empire, and the impressive ruins that endure today all reinforce Rome’s identity as an empire of builders. The study of Roman engineering is enriched by primary sources such as De Architectura (Ten Books on Architecture) by Marcus Vitruvius Pollio, written between 30 and 20 BCE. Vitruvius, born around 80 BCE and deceased by approximately 10 BCE, provided invaluable insights into Roman architectural principles.

The historian Titus Livius (Livy), who lived from 60 BCE to 17 CE, chronicled Rome’s development in his monumental Ab Urbe Condita, while Gaius Plinius Secundus (Pliny the Elder), writing in the first century CE, offered extensive observations on natural sciences and engineering in Natural History. Another crucial source is De Aquis Urbis Romae (The Water Supply of the City of Rome), written in 97 CE by Sextus Julius Frontinus, who served as Rome’s water commissioner after his military tenure in Britain.

While Livy and Pliny recorded Rome’s history, Vitruvius and Frontinus provided technical accounts that, despite their original instructional intent, have become invaluable historical records. These works collectively illuminate the sophistication and enduring impact of Roman engineering, a discipline that helped shape not only the ancient world but also modern architectural and infrastructural developments.

Roman Engineering and Architectural Mastery

The Roman approach to technology was deeply rooted in practical application, as noted by Pliny. The Romans mastered the use of materials, construction techniques, and architectural principles to create structures that not only served their purposes but also symbolized the grandeur and power of the Empire. From temples, marketplaces, and government buildings to aqueducts, baths, and houses, these structures reflected Rome’s dominance and innovation. The engineering wonders of Rome were not merely functional but also conveyed a political message, projecting the strength and stability of the Empire.

Water supply was a crucial aspect of Rome’s infrastructure, and the construction of aqueducts made a lasting impression on both Roman citizens and those in the Mediterranean. The Empire built nearly 800 miles of aqueducts, a proof to their engineering skill and ability to manipulate natural resources for the benefit of urban development. These aqueducts, with their imposing architectural style, stood as visible and enduring symbols of Rome’s authority.

In terms of construction materials, the Romans utilized a variety of stones, each chosen for its strength, durability, and aesthetic appeal. Locally sourced stone was commonly used, while brick and concrete became essential when efficiency and rapid construction were necessary. The tools used for stone masonry—hammers, chisels, saws, and mallets—remained largely unchanged from Roman times to the present day.

Vitruvius, discussed different types of stone, highlighting the importance of travertine for its durability, tufa for its ease of use in interior structures, and marble for its decorative applications. The introduction of extensive marble use during the reign of Augustus significantly influenced the Empire’s architectural aesthetic, as Rome became adorned with vibrant facades of white, red, green, and yellow marble.

Vitruvius also provided insights into Roman preferences for construction materials, offering recommendations based on their qualities and structural resilience. He described tufa as a porous volcanic stone best suited for interior applications, while travertine was praised for its ability to endure stress and harsh weather conditions. The Romans also imported high-quality marble from distant provinces, further reinforcing their architectural grandeur.

Beyond stone, the Romans made significant use of wood in construction.

A wood surface. Credits: Trifonov_Evgeniy from Getty Images Pro, by Canva

Although no wooden structures have survived, evidence suggests that wood was widely used in roofing, staircases, and large-span structures like basilicas. Pliny credited Daedalus with the invention of woodworking tools such as the saw, axe, and plumb-line, highlighting the sophistication of Roman carpentry. Vitruvius elaborated on different timber types, noting the specific uses of oak, fir, cypress, and pine based on their properties. The careful selection and treatment of timber ensured the longevity and stability of wooden structures in Roman construction.

Another noteworthy Roman innovation was the use of glass. While primarily used for vessels and decorative art in the early years, glass was later employed for window glazing by the late first century CE. Pliny’s account of its accidental discovery—where traders inadvertently created glass by heating soda and sand—illustrates the experimental nature of ancient technology. The integration of glass into Roman buildings allowed for more light-filled interiors, enhancing both functionality and aesthetic appeal.

Bricks played a vital role in Roman construction, particularly in areas where stone was scarce. Vitruvius mentioned the use of unbaked mud bricks in early Rome, but by the first century CE, fired bricks became the standard. These bricks were manufactured in standardized sizes—such as the pentadoron, which measured 14.5 x 14.5 inches (36.83 x 36.83 cm)—allowing for rapid and uniform construction.

Baked bricks provided durability and facilitated the expansion of cities, fortifications, and aqueducts across the Empire. The use of brick as a primary building material enabled Rome to construct large-scale structures with remarkable speed and efficiency.

Perhaps the most significant Roman contribution to construction was the development of concrete. This versatile material allowed for the construction of massive vaulted ceilings, domes, and durable structures. Vitruvius emphasized the importance of high-quality sand in concrete production, recommending volcanic pozzolana as a key ingredient.

This discovery revolutionized Roman engineering, as pozzolana-based concrete could set underwater, enabling the construction of artificial harbors, bridge foundations, and other maritime structures. Despite the brilliance of Roman concrete, its use declined after the fall of the Empire and was only rediscovered in 1756 when a British engineer sought a durable material for rebuilding the Eddystone Lighthouse.

In addition to structural materials, the Romans also used plaster, paints, and decorative elements to enhance their buildings. Vitruvius documented the use of various pigments, including blue made from copper and sand, and purple, which was derived from sea mollusks and symbolized imperial power.

The Roman mastery of materials and construction techniques played a fundamental role in shaping the built environment of the Empire. Their architectural achievements, from aqueducts and temples to roads and amphitheaters, not only met the practical needs of a vast and growing civilization but also projected Rome’s power and legacy across time. Even today, the ruins of Rome continue to inspire admiration, a testament to the engineering ingenuity that defined an empire. (Roman Building Materials, Construction Methods, and Architecture: The Identity of an Empire, by Michael Strickland, Clemson University)

The Structural Genius Behind Roman Engineering

Robert Mark, in his article on American Scientist, “Reinterpreting Ancient Roman Structure,” challenges long-standing assumptions about the innovation behind Rome’s most remarkable architectural feats. He argues that while the use of concrete was revolutionary, the true ingenuity of Roman builders lay in their mastery of structural principles developed over centuries. Their knowledge of arch behavior allowed them to construct increasingly ambitious domes, with the Pantheon as the pinnacle of this evolution.

Traditionally, scholars have viewed the Pantheon’s dome as a single monolithic structure, held in place by its massive supporting walls. However, Mark’s structural analysis and computer modeling suggest that the dome functions more like a series of interconnected wedge-shaped arches. This explains how such a vast, unreinforced concrete dome has remained standing for nearly two millennia.

Additionally, his research dispels myths surrounding Roman concrete. Unlike modern reinforced concrete, Roman concrete lacked tensile strength and had to be carefully layered by hand rather than poured. This required architects to design their structures in a way that compensated for its weaknesses.

For example, the Pantheon’s dome exhibits visible cracks that likely developed soon after construction, contradicting the belief that Roman structures were immune to failure. Repairs were made early, showing that even the most advanced Roman engineers faced structural challenges.

Mark also suggests that lessons learned from Roman architecture influenced later Byzantine construction. The Hagia Sophia, built in Constantinople in the sixth century, incorporated windows at the base of its dome—an innovation that may have been a response to the cracking issues observed in the Pantheon.

Roman Marine Concrete

Roman builders developed a pozzolanic mortar capable of being mixed with seawater, a breakthrough that revolutionized maritime construction. This innovation enabled structures to endure for extended periods in the harsh marine environment, paving the way for the expansion of Rome’s harbors, which were crucial for both economic growth and military dominance. The mortar simplified marine construction by eliminating the need for double-walled caissons that would have required draining before work could begin.

By the first century BC, observations of Late Republican maritime structures, alongside Vitruvius’ descriptions, indicated that Roman builders had recognized the superior durability of concrete mixed with volcanic ash. This realization led to the widespread use of pozzolanic concrete in marine environments.

The second century BC saw advancements in standardizing concrete facings for monumental construction in Rome, which not only improved the efficiency of building but also reduced reliance on formwork. By the first century BC, techniques integrating dimension stone with concrete masonry were refined, and during the Augustan era, innovations in architectural concrete became standardized in both material selection and mixing procedures.

Given the complexities of marine construction, the materials and techniques required for pozzolanic concrete were subject to careful refinement. Vitruvius dedicated considerable attention in De architectura to describing the production and placement of marine concrete, providing more detailed guidance than on terrestrial concrete techniques.

Studies such as ROMACONS have revealed a diverse tradition of formwork designs across the Mediterranean, which varied according to local conditions and available resources.

A wall painting depicting a harbour landscape scene, found in Herculaneum. Credits: ArchaiOptix, CC BY-SA 4.0

Despite the significance of these advancements, there is no surviving ancient record detailing how these engineering innovations spread beyond Central Italy. Vitruvius himself acknowledged that earlier Roman architects and engineers had not left organized, publicly accessible records of their techniques.

His De Architectura sought to fill this gap, offering insights into both terrestrial and marine mortar compositions based on empirical observation. One of his objectives was to provide villa and farm owners with knowledge that would allow them to oversee their own construction projects, suggesting he intended his work for wide circulation.

Vitruvius’ ambition for his work to endure beyond his lifetime proved correct. De Architectura remained influential for centuries, epitomized by Faventinus and later referenced in Palladius' agricultural handbook. Its significance persisted through the medieval and early modern periods, cementing its place as one of the most enduring technical treatises on Roman engineering.

Piscinae, Prestige, and Marine Concrete: Roman Aristocracy and the Development of Maritime Engineering

The earliest surviving examples of marine concrete construction in Rome are not large harbors but rather the fish-raising ponds (piscinae) built by aristocrats along the western coast of Central Italy in the first century BC. These piscinae, praised by Pliny as an innovation of L. Licinius Murena, served both practical and prestige purposes.

Initially popular among the elite, they later declined in favor of larger industrial fish farms, such as those at Cosa. Though piscinae were a relatively minor element of Roman marine construction, their significance lies in their role as precursors to the grand Imperial harbors. Unlike those later structures, the social and technological contexts of piscinae are better documented in contemporary sources, including Varro, Cicero, and Columella.

Marine concrete used in piscinae demonstrated early Roman expertise in hydraulic engineering. Many were constructed with standardized, durable mortars containing volcanic ash from the Gulf of Naples, as evidenced in the materials of the Santa Liberata piscina. The knowledge gained from building these pools likely contributed to the Romans’ ability to construct submerged bridge foundations, such as those commissioned by M. Fulvius Nobilior in 179 BC for the Tiber River, and later, the great Imperial harbors.

Aristocratic villa owners played an active role in the design of these piscinae, which often included elaborate compartmentalization to separate fish by species and size. Varro likened their arrangement to an artist’s paint box, suggesting that aesthetic considerations were as important as function. Lavish projects such as those by C. Sergius Orata, who built extravagant piscinae near Puteoli, demonstrate the social prestige attached to these structures. Orata even developed heated bathing pools, later known as pecularia…maria or "personal seas".

Over time, these projects evolved beyond personal luxury. By the first century AD, Columella argued that saltwater piscinae could be profitable businesses, reflecting the increasing economic importance of fish-farming. This shift paralleled advances in marine concrete technology, which became essential for Imperial harbor construction.

Piscinae required careful circulation of seawater to maintain fish health, a concern echoed in later harbor engineering, where similar principles were applied to prevent sedimentation. Seneca even described these pools as "harbors for extravagance", linking them conceptually to the monumental harbors that would define Rome’s maritime dominance.

The methods developed in piscinae—including the use of volcanic ash, submerged concrete forms, and breakwaters—provided direct precedents for large-scale Roman harbor construction. The knowledge gained from villa-based marine engineering projects likely informed the sophisticated harbor-building techniques used in places like Portus, Antium, and Centum Cellae.

This transition from aristocratic indulgence to Imperial infrastructure reflects a broader Roman pattern: technological innovation often began in private luxury before being adapted for state expansion. (Building for eternity: The history and technology of Roman Concrete Engineering in the sea, by C.J. Brandon, R.L Hohlfelder, M.D Jackson and J.P Oleson, with contributions by

L. Bottalico, S. Cramer, R. Cucitore, E. Gotti, C.R. Stern and G. Vola)

The Evolution of Roman Construction Methods

As the Roman Empire expanded, the development of standardized and efficient construction methods became a necessity. Brick and concrete emerged as fundamental materials, but their effective use required advancements in construction techniques. Roman builders refined these techniques over time, leading to the widespread implementation of distinct masonry styles.

A crucial step in Roman construction was the foundation. While modern large structures typically rely on bedrock, Roman foundations consisted of large stone rubble mixed with mortar, typically around three feet deep (±0.9m). These foundations, found across Roman ruins, suggest a relatively standardized approach, though they do not always indicate the type of structure they once supported.

Roman concrete construction was categorized by its facing, with three primary types: opus incertum, opus reticulatum, and opus testaceum. In all three methods, concrete was poured between two layers of facing material, with walls typically measuring two to three feet (±0.6-0.9m) thick.

Opus incertum, the earliest technique, consisted of irregularly shaped stones gathered from local sources. It was widely used in fortifications and walls but began to decline in the first century BC as Rome’s population and economy expanded.

The demand for construction efficiency led to the development of opus reticulatum, a technique in which stones were cut into standard square shapes and laid diagonally to create a uniform, net-like pattern. This innovation transformed construction work, shifting the laborer’s role from craftsman to assembler.

The transition from opus incertum to opus reticulatum is evident in some structures, such as the cistern at the Forum Baths in Pompeii, where the lower levels feature the newer method while the upper levels revert to the older style. The use of opus reticulatum became widespread by the first century BC, as confirmed by Vitruvius, who stated that it “is used by everyone now.” Its popularity stemmed from both its practicality and its aesthetic appeal.

By the late first century AD, opus testaceum, or brick-faced concrete, became the dominant construction technique. Unlike earlier methods that used irregularly shaped or diagonally placed stones, opus testaceum utilized baked bricks laid in horizontal courses.

This transition marked a significant step in the standardization of Roman building materials.

Opus incertum on the Temple of Jupiter Anxur in Terracina, Italy. Credits: antonioa89, CC BY-SA 3.0

While the exact date of its introduction remains uncertain, its widespread use is evident in some of Rome’s most iconic structures, including the Colosseum, Trajan’s Market, the Pantheon, the Tomb of Hadrian, the Baths of Caracalla, and the Basilica of Maxentius. The Colosseum, in particular, showcases the refinement of Roman brickwork, with its tiered arches and precisely placed keystones forming an intricate yet structurally sound design.

The shift to opus testaceum reinforced Rome’s architectural dominance, enabling faster, more durable construction. The vast remnants of brick-faced structures in and around Rome stand as enduring evidence of the Empire’s architectural and engineering expertise.

As one scholar noted,

“The strongest visual memory left in the minds of those who have visited Rome and its vicinity is one of the monumental body of brick from which there emerge, now and then, some isolated remains of travertine or marble.”

Indeed, the sheer volume of surviving Roman brick structures highlights the lasting impact of their construction techniques, which allowed the Empire to rapidly expand and build an enduring architectural heritage.

About the Roman Empire Times

See all the latest news for the Roman Empire, ancient Roman historical facts, anecdotes from Roman Times and stories from the Empire at romanempiretimes.com. Contact our newsroom to report an update or send your story, photos and videos. Follow RET on Google News, Flipboard and subscribe here to our daily email.

Follow the Roman Empire Times on social media: